| "It needed some help."

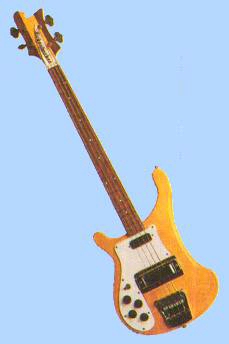

Mark Arnquist worked at the Rickenbacker factory "from July 1972 to October 1976. I was the lead man in charge of the area from when the instruments came into the finishing building until [owner] F.C. Hall picked them up in a van in the afternoon. I worked on most of the instruments to be repaired in that time frame, and if there was a need for structural or any fret work, I got the job. "The P.M. bass came back to the factory prior to the 'Wings over America tour.' It needed some help. The original cast bridge was cracked, and the saddle assembly rattled and was sagging. The horseshoe magnets were dead. The coil was fine, but the cobalt magnets -- stone dead. The frets needed some serious dressing and a new nut. (He has played around with a zero fret extension over the years, and the bass originally had a stock nut) . . . The finish was nothing at all. It had the patina of dirty wood and sweat. It didn't stink of armpits, but it was not sealed, and we actually discussed sealing for him. We decided not to, as we were already doing work that was not asked for." And then there was the do-it-yourself sanding job . . . "The whole bass was not stripped by a professional at all. There were plenty of hack marks and sandpaper gouges . . . The horns just appeared to have been scraped and sanded too much. The front and the back were fairly well done but all of the edges and contours were done amateurishly . . . The bass was definitely his; the original Fire-glo was still in the routes, and under the pickguard there was still some finish." The Rickenbacker doctors operate "The team that worked on it was four guys: Arlo (given name Howard, I cannot rememmber his last name) in the electronics area; Joel Heline in check out; Gene Garbis in woodshop/fretting, and myself at the assembly bench and at the buffing area. We had a gathering of minds, and after sending the cobalt magnets out for charging we got the bad news that they would not hold a charge. Bill Myers (plant manager) gathered us and we discussed our options. "We opted for a custom coil/pickup for 'The Man.'

The idea was to overwind a stock coil for a 4001. This is what he

got. The tailpiece was replaced with a new casted piece and saddle assembly.

The saddles were cut/spaced using calipers, not the normal eyeball method,

and the saddles were buffed to a high sheen. "This group was really into this job. Lots of love and care went into what we did. After a few of the staff looked at it, Jim Ruthledge (the only lefty bassist in the factory) played it. He loved what we had done. And off it went." (c) 2001-2004 John F. Crowley |

The fret work was done by Gene, and then I got the bass after it came back

into the finishing building. I leveled and buffed them, then assembled

it. Joel was the next to get it, and he made a bone nut for it.

There were some blanks left over in Bill's desk, and one of them was used.

Then it was filed and restrung with the strings that it came in with .

. . [McCartney] only

sent it in to get the horseshoe pickup fixed. We took it upon ourselves

to do all this work.

The fret work was done by Gene, and then I got the bass after it came back

into the finishing building. I leveled and buffed them, then assembled

it. Joel was the next to get it, and he made a bone nut for it.

There were some blanks left over in Bill's desk, and one of them was used.

Then it was filed and restrung with the strings that it came in with .

. . [McCartney] only

sent it in to get the horseshoe pickup fixed. We took it upon ourselves

to do all this work.